- All

- Coal Crusher

- Coke Cutter

- Haulage

- Power Winch

- Vibrator

- Conveyor Materials

Coal Crusher (5 No. Size) Single Disc

Type : Coal Disintegrator

A Coal Crusher (5 No. Size) Single Disc is a type of coal disintegrator designed for pulverizing coal into smaller particles. This equipment typically features a single rotating disc that crushes the coal fed into it, breaking it down into finer granules suitable for various industrial applications. Its design and operation are focused on efficiently reducing coal sizes while ensuring uniformity and consistency in the output. This type of coal crusher is commonly used in industries such as mining, power generation, and metallurgy for processing coal for combustion or further processing.

Specifications :

- Driven by: 80 - 120 H.P. Electrical Motor

- Coal Feed Size: below 125 mm

- Crushed Coal Size: below 2 mm

- Coal Crushing Capacity: 8 to 10 Tons per Hour

- Crusher’s Body: 12 mm thick

- Manganese Steel Top & Side Liner Jaw Plate

- Six Nos. Hammers provided in this Crusher

Coal Crusher (5 No. Size) Double Disc

Type : Coal Disintegrator

A Coal Crusher (5 No. Size) Double Disc is a type of coal disintegrator designed for pulverizing coal into smaller particles. This equipment typically features a single rotating disc that crushes the coal fed into it, breaking it down into finer granules suitable for various industrial applications. Its design and operation are focused on efficiently reducing coal sizes while ensuring uniformity and consistency in the output. This type of coal crusher is commonly used in industries such as mining, power generation, and metallurgy for processing coal for combustion or further processing.

Specifications :

- Driven by: 160 - 200 H.P. Electrical Motor

- Coal Feed Size: Below 150 mm

- Crushed Coal Size: Below 2 mm

- Coal Crushing Capacity: 20 to 25 Tons per Hour

- Crusher’s Body: 12 mm thick

- Manganese Steel Top & Side Liner Jaw Plate

- Twelve Nos. Hammers provided in this Crusher

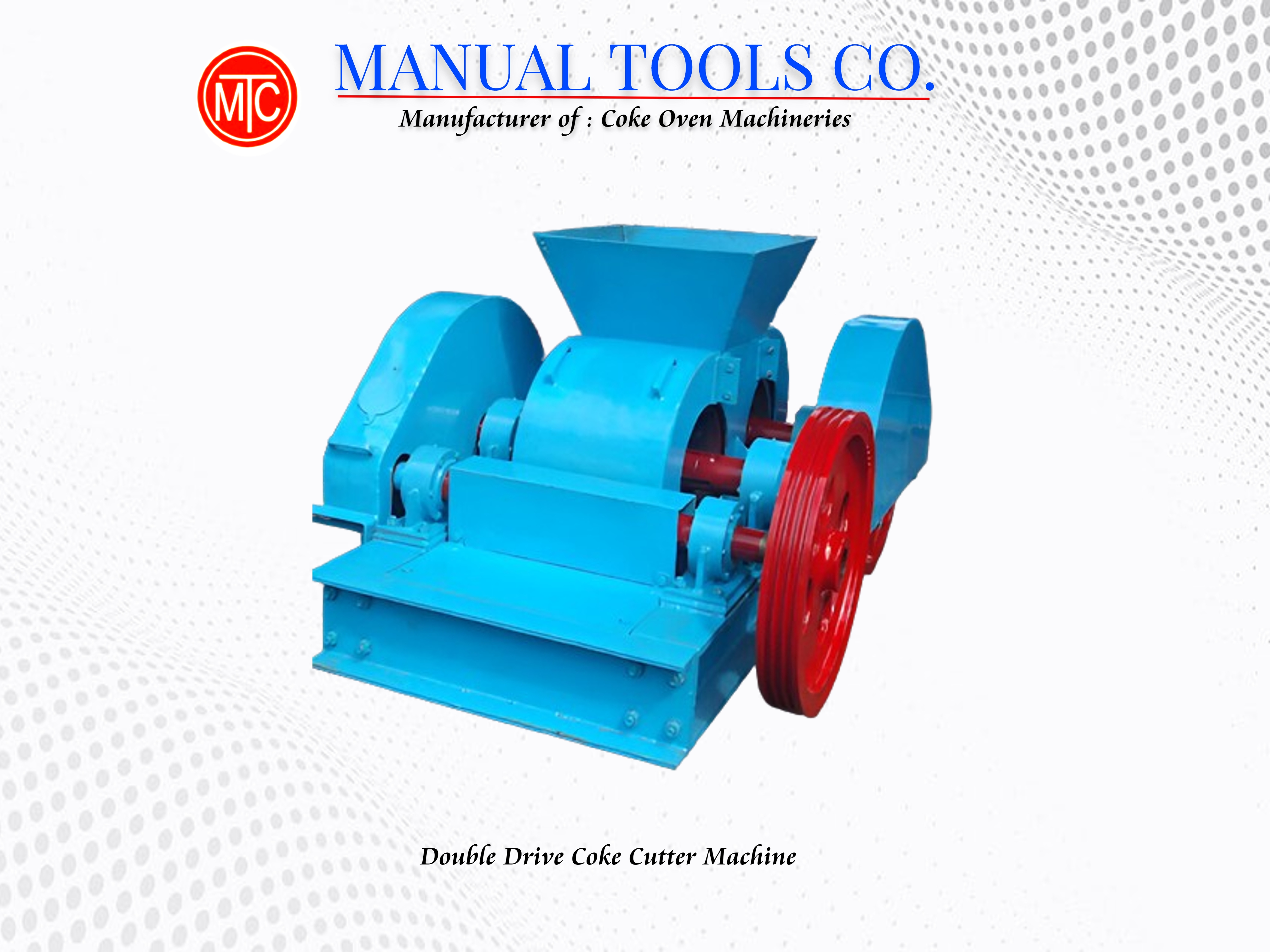

Coke Cutter Machine (Double Drive)

Type : Coke Cutter

The Coke Cutter Machine (Double Drive) is a specialized industrial equipment designed for efficiently cutting and slicing coke blocks used in various manufacturing processes. Featuring a double drive system, it ensures enhanced power and precision during operation. This machine streamlines the cutting process, increasing productivity while maintaining quality standards. Ideal for industries reliant on coke as a crucial raw material, it offers reliability and performance in handling bulk quantities.

Specifications :

- Driven by: 20 H.P. Electrical Motor Both Side

- Coke Feed Size: Below 200 mm

- Finished Coke Size: Below 60 mm

- Coke Breaking Capacity: 12 to 15 Tons per Hour

- Manganese Steel Replacebale Liner Teeth

- Cast Steel Machine Cut Gear & Pinion Both Side

Haulage Machine

Type : Haulage

In the coke oven industry, the haulage machine serves a vital function by pulling coke from the coke ovens. This specialized equipment is designed to efficiently extract the coke, a valuable product of the coking process, from the ovens. Equipped with robust features and powerful pulling capabilities, haulage machines are essential for maintaining a steady flow of coke production. Their reliable performance ensures smooth operations and contributes to the overall efficiency of the coke oven industry.

Specifications :

- Driven by: 10 H.P. Electrical Motor

- Pulling Capacity: 10 Tons

- Gearbox Type: Worm Reducer

- Cast steel machine-cut gear and pinion

Power Winch

Type : Door Lifter

The Power Winch Door Lifter is essential in industrial settings for lifting heavy Coke Oven doors. Its robust design and adjustable features ensure safe and efficient handling, reducing workplace risks and downtime. With precise control, it enhances productivity in Coke Oven maintenance and production operations.

Specifications :

- Driven by: 7.5 H.P. Electrical Motor

- Door Lifting Capacity: 2.5 to 3 Tons

- Gearbox Type: Worm Reducer

- Cast steel machine-cut gear and pinion

Vibrator Screen Machine

Type : Screening Machine

The Vibrator Screen Machine efficiently sorts various grades of coke by size using vibrating mechanisms. Its versatility and robust design make it ideal for different types of coke, ensuring uniformity and quality in the final product, thereby enhancing productivity in coke processing operations.

Specifications :

- Driven by: 7.5 H.P. Electrical Motor

- No. Of Decks: 1 Deck | 2 Deck | 3 Deck

Conveyor Materils

Type : Conveyor

Conveyor materials are crucial in the coke oven industry, facilitating the efficient movement of coal, coke, and by-products throughout the production process. High-quality belts, rollers, and chains ensure smooth operation, while robust frames and motors support heavy loads. These materials endure extreme temperatures and harsh conditions, vital for uninterrupted coke oven operations.

Stock :

- Idler with Roller

- Return Rollers

- Impact Rollers

- Head Pulley

- Tail Pulley

- Available in different sizes