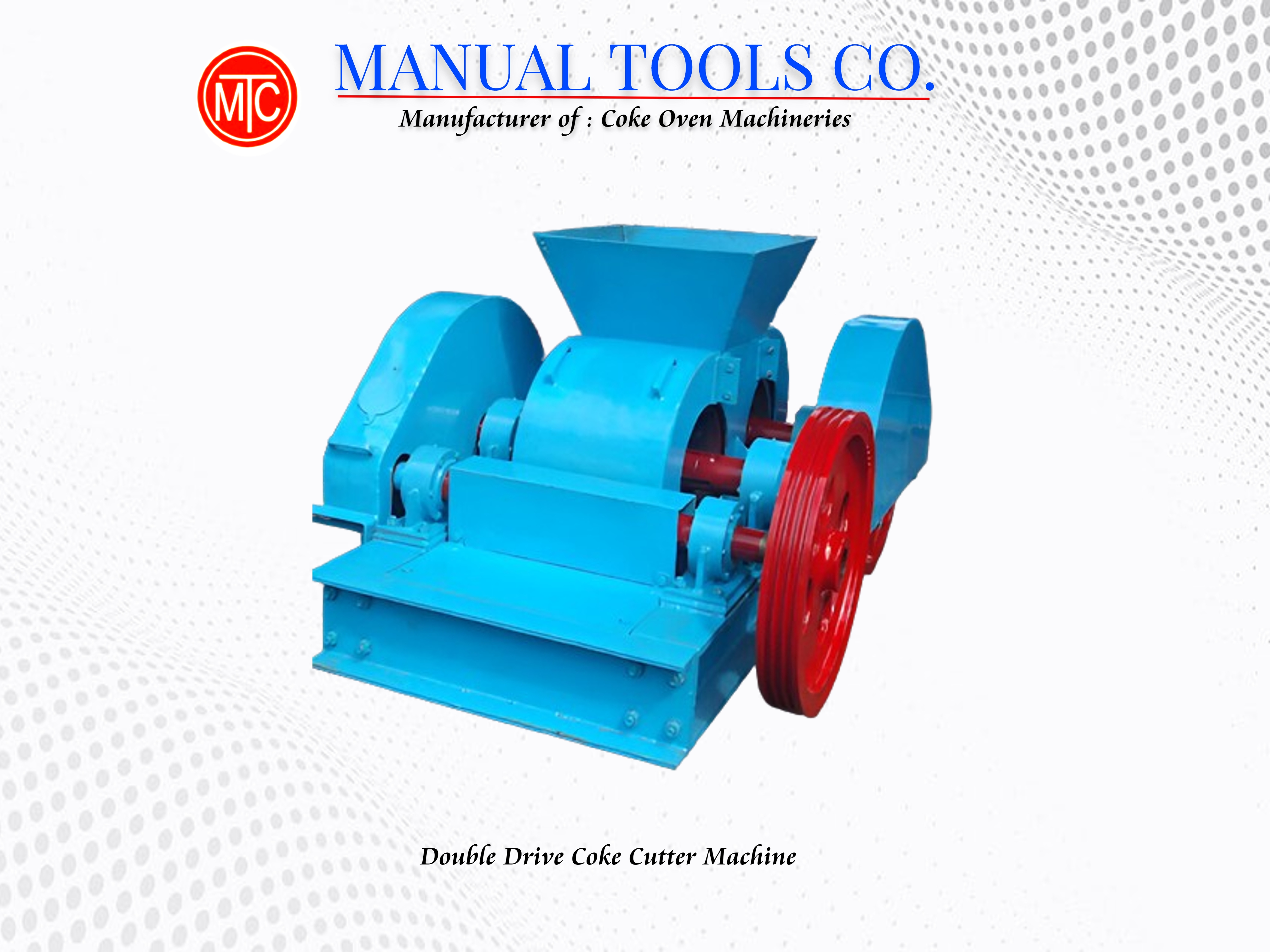

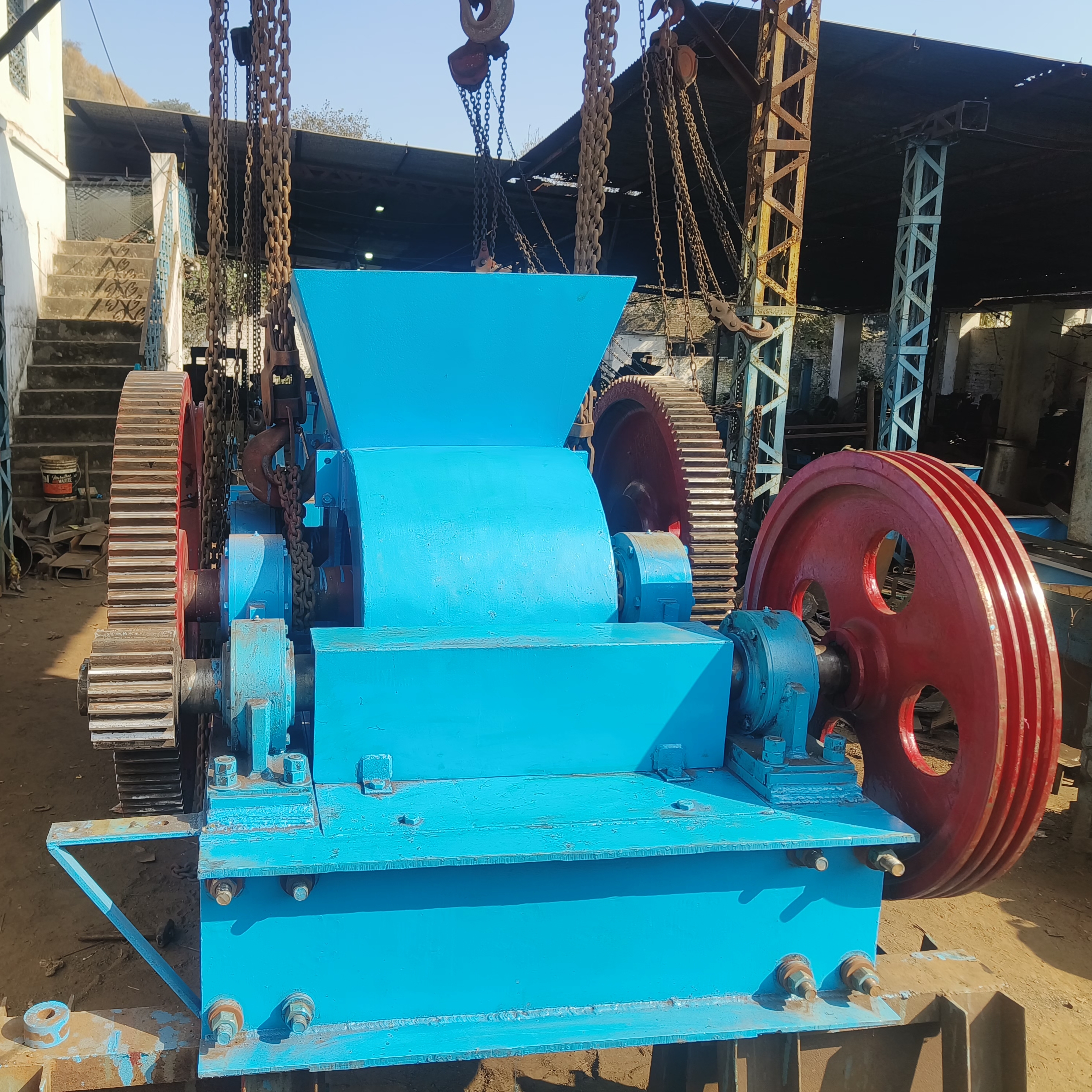

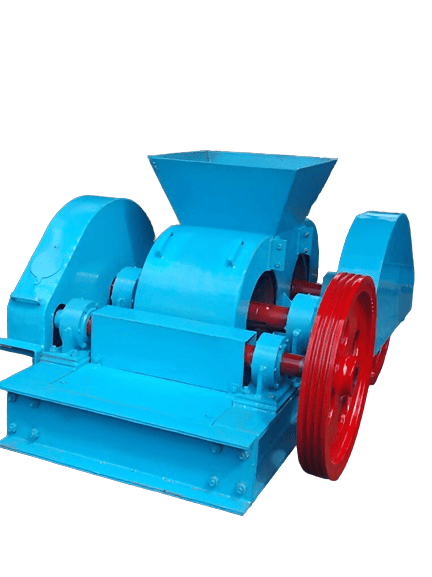

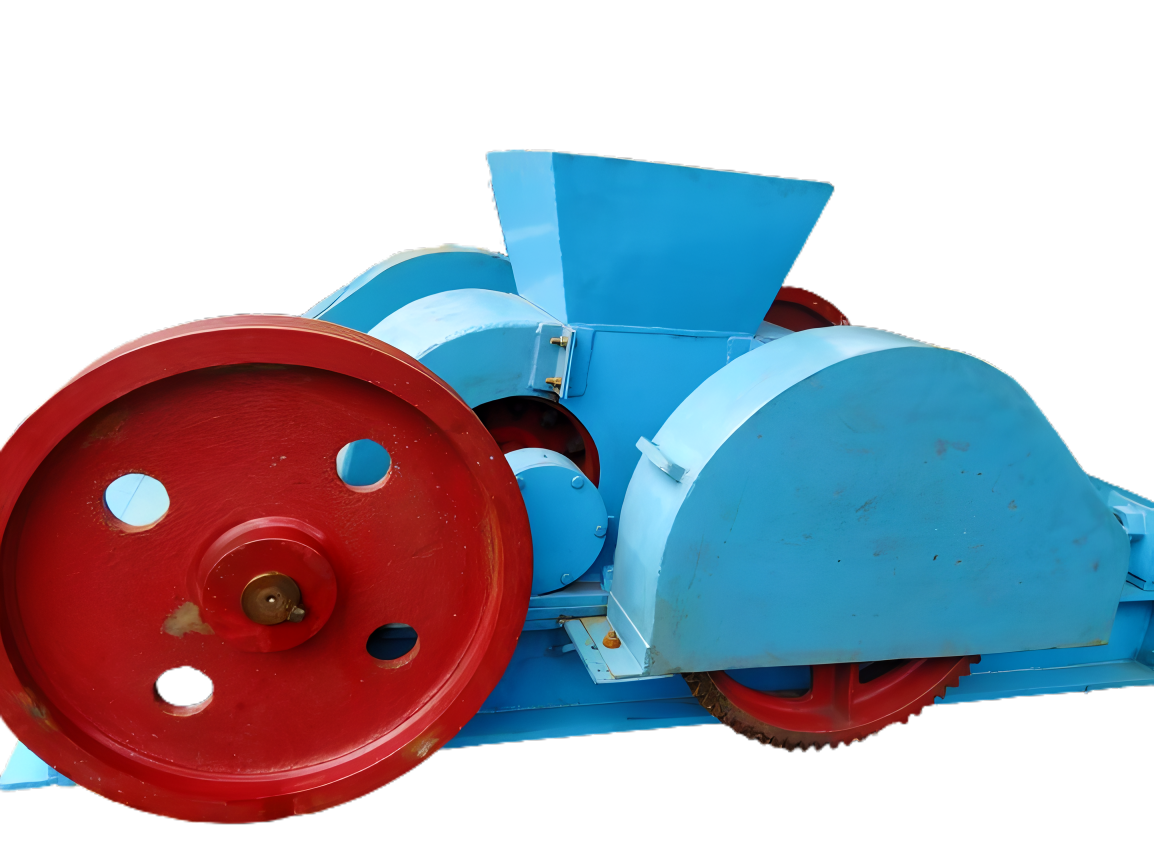

Coke Cutter Machine (Double Drive)

Built for maximum torque and power, this double-drive cutter features dual 20 HP motors and cast steel gears. Its adjustable drum system ensures uniform output sizing (45-60mm) while manganese steel liner teeth guarantee longevity under heavy loads.

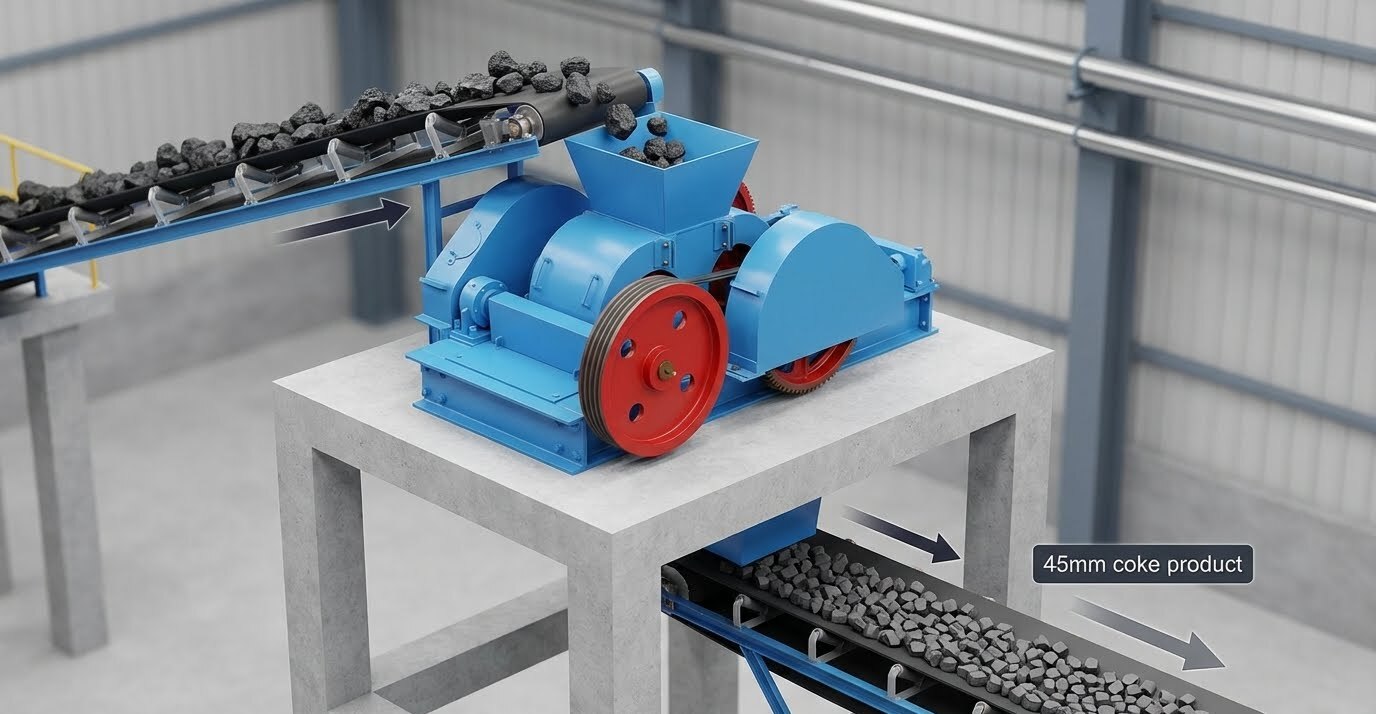

Operational Process Flow

Visualizing the efficient material handling of the Double Drive Coke Cutter.

Continuous Production Cycle

1. Material Feed

Raw coal/coke lumps (up to 200mm) are delivered via the upper conveyor belt directly into the machine's intake hopper.

2. Double Drive Cutting

The dual 20HP motors power the crushing drums, efficiently breaking down the material without jamming, ensuring high throughput.

3. Output

Uniformly sized 45mm coke product (adjustable up to 60mm) is discharged onto the lower conveyor belt for immediate transport.

Product Gallery

Detailed views of the double drive mechanism and cutter teeth.

Common Questions

Specifics about the Double Drive model.